If you are not familiar with the new library, we recommend you first read the previous posts in this series ( Conveyors and AGVs and transporters). Please note: this post is for those who want to understand the intricacies of modeling conveyor networks. It can also be launched on this page, directly from AnyLogic Cloud.

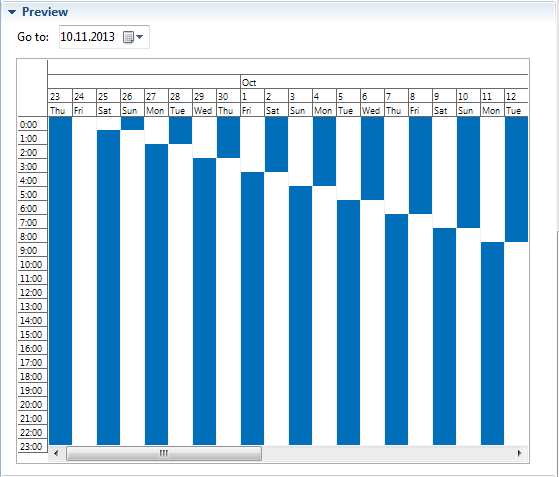

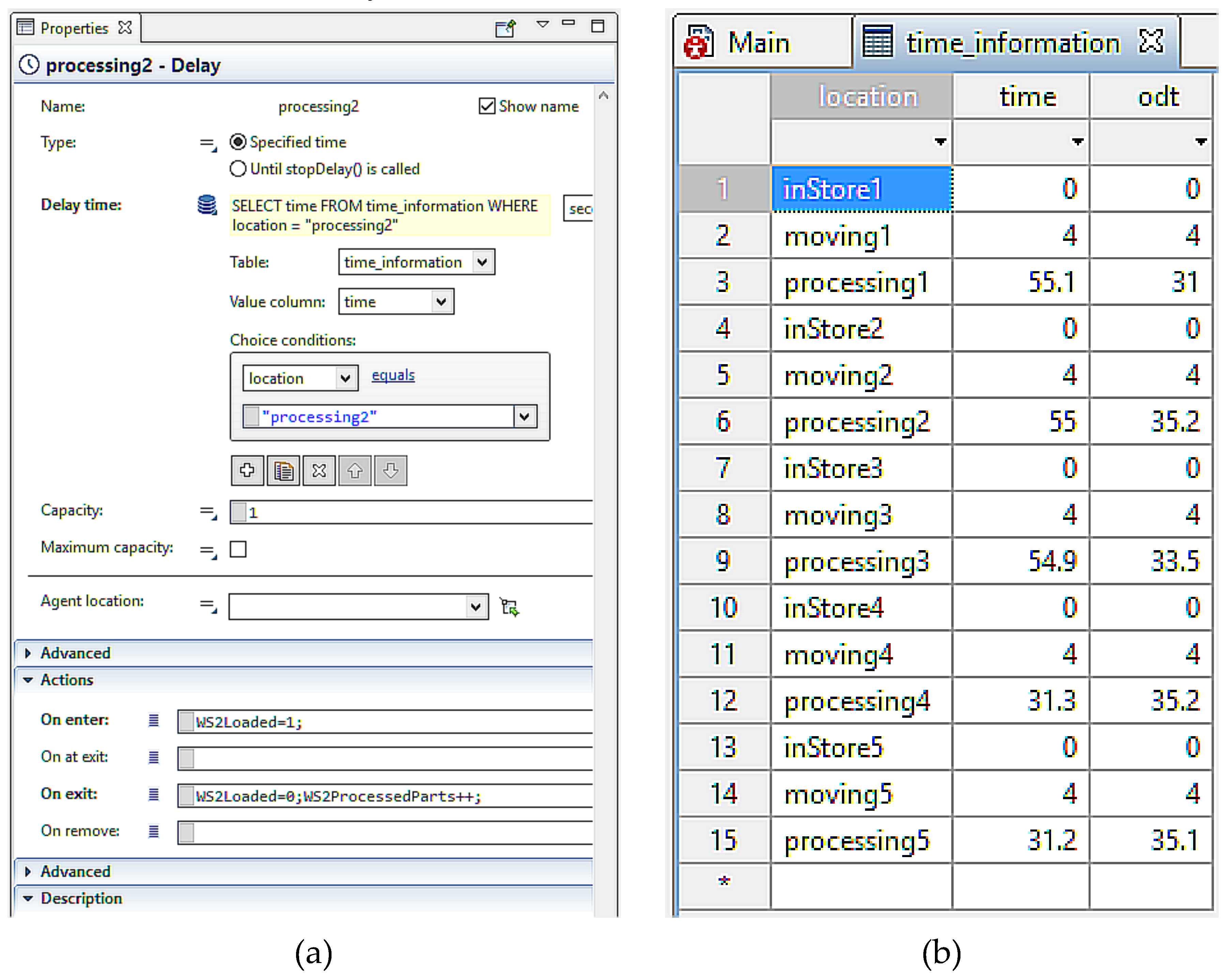

This model can be found in the list of examples on the AnyLogic home page, in the Manufacturing section. Model statistics allow you to estimate the total utilization of the conveyor network and equipment, as well as the duration of the production cycle and production rates. The model shows the processes that prepare solar cells for solar panels and how the solar modules are manufactured. Using the Solar Panel Production Line model, we will explore the Material Handling Library and learn how to use Station element. It simplifies the modeling of production processes when it can be represented by a delay or the transition of an agent to a new state. To do this, AnyLogic uses the Station markup element. This allows you to reproduce production processes and account for the mechanical or manual processing time needed, working hours, and station scheduling.

Included in the Material Handling Library is the ability to simulate the processing of items at stations on a conveyor network. It is the third in a series – the first two beginning with the basic functionality of the library and how to model conveyors and transporters. The Material Handling Library is a major part of AnyLogic and this ‘how-to’ explores how to get started with the library. See how simulation improves material handling in our whitepaper!

0 kommentar(er)

0 kommentar(er)